Assembly & Testing

To complement our extensive design and manufacturing capabilities, Renown Group has in-house assembly and testing facilities that ensure we are able to meet our client’s additional project needs.

Assembly

Renown Group can complete the final assembly of complex components to deliver fully furnished, functional products. We can provide:

- Gas tight assembly

- Blast & fire rated assembly

- Hydraulic assembly

- Pneumatic assembly

- Mechanical assembly

Testing

Renown Group are able to provide a wide range of verification and testing techniques.

Our in-house capabilities cover, Load testing, pressure testing, hardness testing and Non-destructive testing. (Visual, MPI, DPI, UT)

Our technicians and working procedures are CSWIP / PCN / ASNT qualified and endorsed.

We have an inhouse 800t load test capability and are able to provide local onsite load testing & NDT services.

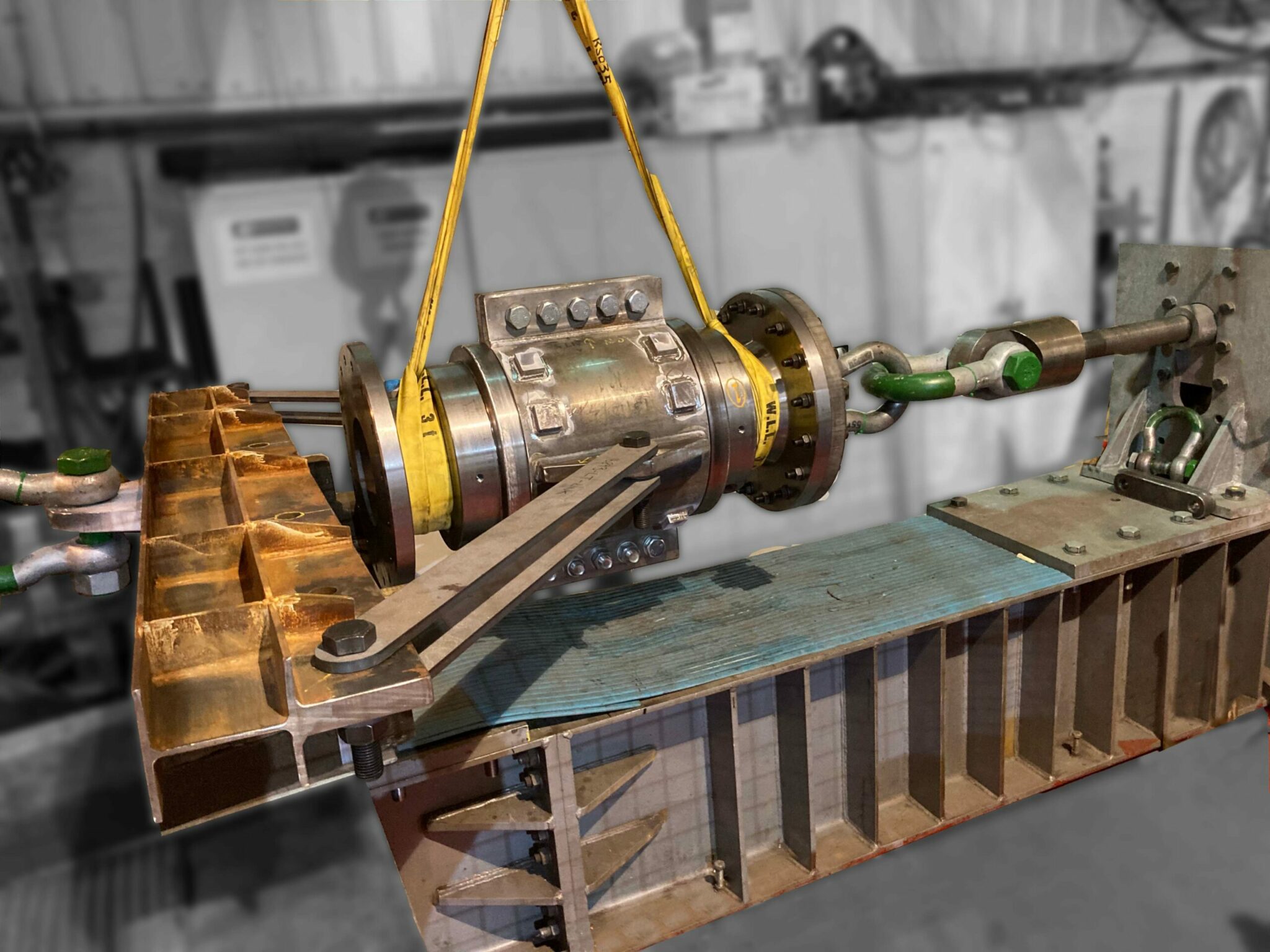

Load Testing

Our 5m long load test bed is capable of testing components up to 1.1m in width/diameter 4m in length to a max load of 55 tonnes.

We also provide load testing capability utilising several jacking systems ranging from 50kg up to 1200 tonnes.

Our Load Testing facility is serviced by an overhead crane.

Turnkey packages can be provided which includes design, manufacture, installation, commissioning, servicing, full control systems and bespoke pallets & tooling.