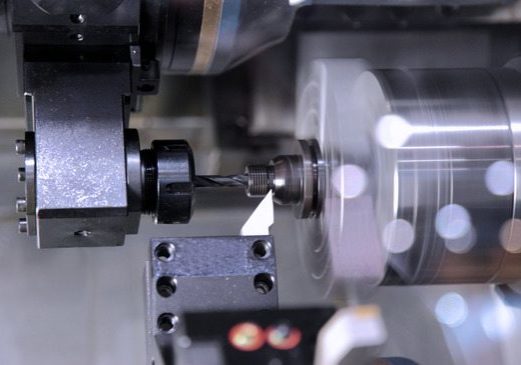

Machining

Machining Services

(Info-sheet)

Capabilities

At Renown Group we use a variety of CNC services including Milling, Turning, Vertical and Horizontal boring.

Backed by 3d cad/cam and 4 and 5 axis capabilities our skilled machinists can produce parts from a wide range of materials including alloy, stainless steels, armour steels and exotic materials.

Plant & Equipment

Renown Group use the latest DNC technology to reduce manufacturing process time and maximise spindle cutting times, as well as a fully integrated ERP system and CAD CAM software.

- CNC Verticals – 3000 mm x 1400 mm.

- CNC Turning – 700 mm dia x 3000mm long.

- CNC Horizontal Boring – 800 mm dia with twin pallets.

- CNC Vertical boring.

- AlphaCam 3D model manipulation.

- Faro Arm Inspection.

- CMM Inspection.

- Stocked tooling vends and store

Enhanced Productivity

As a specialist contract service provider to the energy and defence sectors our customers benefit from inherent advantages of focused expertise and flexibility. Rapid response to enquiries is a key factor in maintaining high levels of customer service.

A dedicated team of highly experienced production and quality specialists enables Renown to develop and deliver enhanced technical solutions cost effectively.